- full engineering input to meet customer objectives, support problem resolution, systems development, performance optimisation and test programme delivery -

- a particular strength is early development phase work, adapting and modifying existing engines to use future technology and hardware as demonstration mule engines and the skill to achieve first fire and run in -

Our Facility

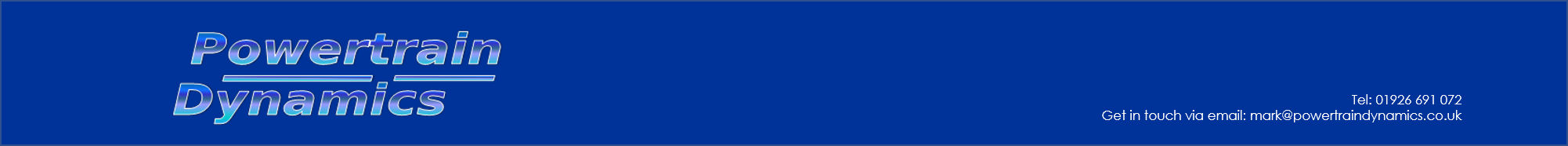

• Our facility houses three dynamometer test cells which are supported by fully automated systems to allow remote running as well as manual running

• Our infrastructure and set-up means we can perform one-off manual tests and 24-hour, 7-day a week continuous running

• We are able to deal with gasoline, diesel and specialist fuels

• On site support services to facilitate testing:

- Engine build shop

- Teardown / layout area

- Instrumentation supply and installation

- Fabrication and welding (MIG and TIG)

- Manual machining

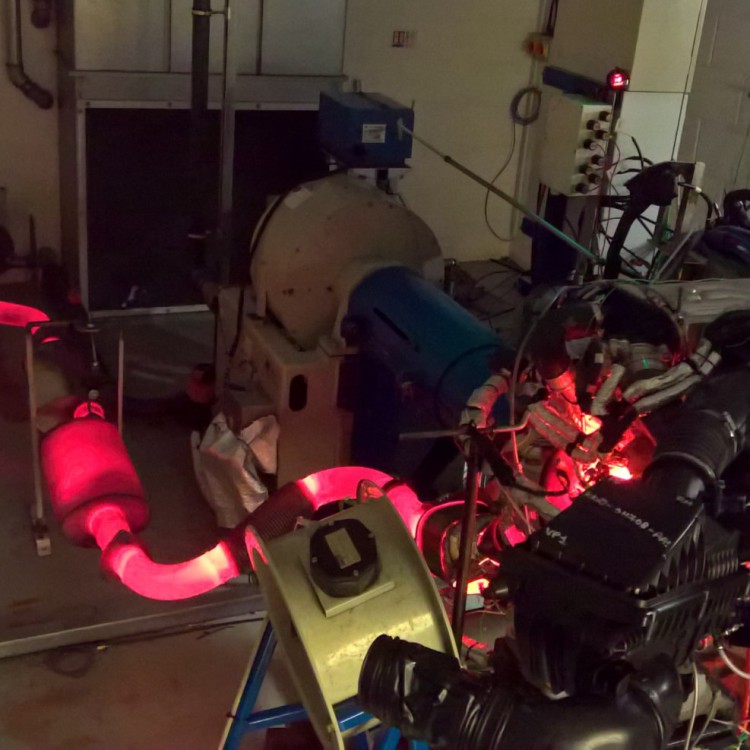

Our Dynos

• Three absorption dynamometer equipped test cells

• 550kW power capability

• 10,000rpm speed capability

• Fully automated REO-ETCTM real-time control systems

• Sierra CP Fuel Trak fuel measurement system

• 48 k-type temperature measurement channels

• 26 pressure measurement channels

• 16 analogue voltage measurement channels

• Turbo speed measurement

• Cylinder pressure and combustion analysis

• ASAP3TM link for ECU development tool/data transfer e.g. ETAS INCATM

•1Hz and 10Hz continuous trend log data rates with 100Hz available on selected channels (user definable averaged step logs)

• Expandable channel count (CoTS I/O modules up to 1024 recordable channels)

R&D Testing Services

• Functional mechanical systems tests and development

• Quasi-transient durability cycling

performance development

• Design change / prototype prove-out functional testing

• Steady state calibration development

• Run and rate testing

•Emissions testing AVL i60

• New technology evaluation testing

• New technology system characterisation testing

R&D Engineering Services

We offer a wide range of engineering services to support OEM testing programmes. We are particularly strong in prototype and pre-production development phase work. Our expertise includes:

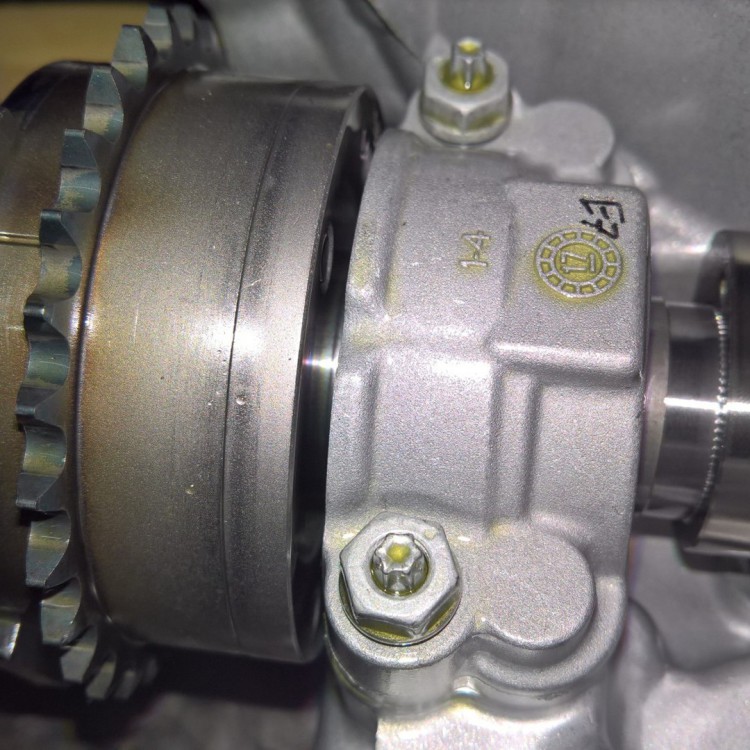

• Engine build and modification

• Engine tear down and layout

•Component analysis for failure modes and performance

•Technology prove out and prototype validation from work horse to production verification development phases

• Systems development to meet functional or legislative targets

• Issue identification, reporting and resolution support

• Data reporting