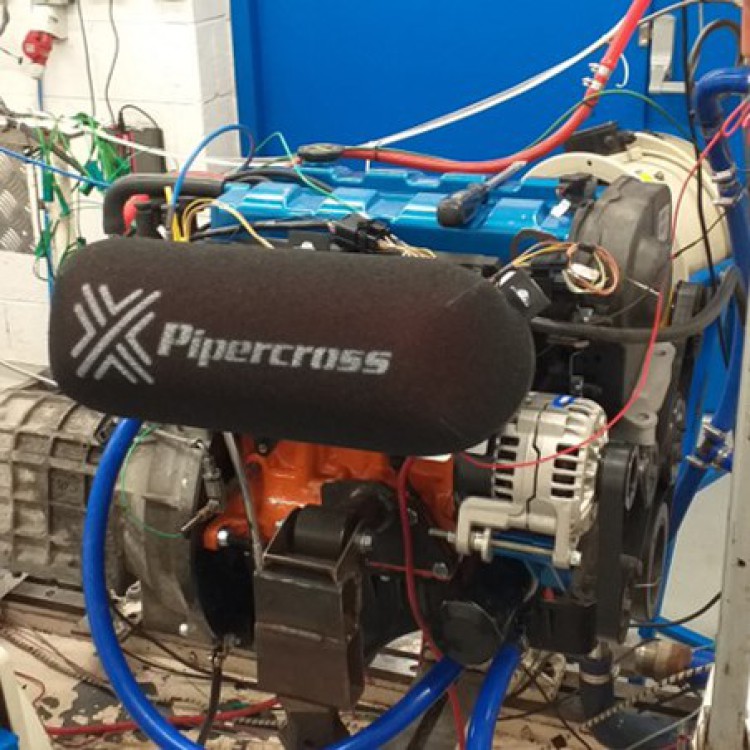

- full engine build or modification of existing race engines -

- bespoke engine testing or development -

- fault-finding and diagnostic work to restore or improve performance -

Our Facility

• Our facility houses three dynamometer test cells which are supported by fully automated systems to allow automatic and manual running

• Our infrastructure and set-up means we can run one-off manual tests e.g. Power Curve to 24-hour race simulation cycles

• We are able to deal with gasoline, diesel and specialist fuels

• On site support services to facilitate testing:

• Engine build shop

• Teardown / layout

area

• Instrumentation

supply and

installation

• Fabrication and

welding

• Manual machining

Our Dynos

• Three absorption dynamometer equipped test cells

• 550kW power capability

• 10,000rpm speed capability

• fully automated REO-ETCTM real-time control

systems

• 24 hour-a-day, 7 days-a-week engineer supported running

• 48 k-type temperature measurement channels

• 26 pressure measurement channels

• 16 analogue voltage measurement channels - Lambda meter etc.

• Turbo speed measurement

• Cylinder pressure and combustion analysis

• CAN interface link for ECU development tool/data transfer - supports all after-market CAN ECUs

•1Hz and 10Hz continuous trend log data rates with 100Hz available on selected channels (user definable averaged step logs)

• Expandable channel count (CoTS I/O modules up to 1024 recordable channels)

Our Race and Competition Engine Testing Services

• Functional mechanical systems tests and development

• Quasi-transient cycling for race simulation

• Performance development

• Design change / prototype prove-out functional testing

• Steady state calibration development

• Run and rate testing

• New technology evaluation testing

• Homologation testing

• One-make series engine batch performance validation testing

• Engine upgrade system characterisation testing

• Vibration survey for durability/fatigue investigation

• Thermal survey for heat balance and cooling system development

Race and Competition Engine Development

We offer a wide range of engineering services to support Motorsport testing programmes:

• Engine specification development to meet customer targets

• Engine build/modification

• Engine tear down and layout

•Component analysis for failure modes and performance

• Systems development to meet functional or legislative targets

• Issue identification and resolution

• Dry sump system design and development

• Breather development

• Induction system performance design and development

• Exhaust system performance design and development

• Performance evaluation

• A-B-A-B component performance evaluation

• Competitor engine benchmarking

• Powertrain integration

• Turbo matching